8K DCI RAW scanner for 35mm film in fragile state

The digitization of highly fragile film, a complex problem

As a Specialist Technician in the digital department of the Filmoteca de Cataluña Conservation and Preservation Center (2CR), I had the opportunity to explore the complexity associated with the correct advancement of film material through digitization systems when physical degradation affected the integrity of the film support. The challenges that arise in these cases may require the incorporation of alternative solutions, specifically adjusted to the characteristics of these exemplars, to enable the successful completion of the digitization processes.

Background

Due to their design, the 35mm film scanners that we find on the market may not be designed to accommodate film in highly fragile states. In such equipment, the scanning process carries the possibility of causing physical damage to the material.

The usual mechanisms for driving the film are usually sprocket wheels that pull from the lateral perforations of the film support or sprocketless rollers. Both need to maintain a degree of tension on the film support to guarantee the correct movement and synchronization of the film within the digitizing system.

The problems appear when we handle parts of the footage where the perforations do not exist or are damaged, or when we work with fragments of film that, due to their fragile condition, do not tolerate a certain degree of tension. In these circumstances, the advance flow of the film stops or is altered, causing a long list of errors in the results of the digital capture and, in the worst of situations, the film support itself can be moved incorrectly, resulting in even more damage when being bitten in an unwanted way by one of the rollers.

In any case, the repeated need to repair the material in the middle of a work session —resulting in the removal of the film from the equipment and forcing the process to be restarted with each new break— ends up transforming the digitization process into an uncertain reality.

An intermediate design

In an attempt to solve the problems associated with the aforementioned drive mechanisms, the use of traditional flatbed scanners may initially seem like an alternative to be considered. Although these devices offer a degree of optical resolution that has improved over the years, and some include accessories for digitizing small segments of 35mm photographic film, we cannot forget that due to their design they are more intended to respond to other workflows, with formats and documents that we usually find more commonly in office environments, rather than for the advanced digitization of 35mm film rolls.

However, the bases of its operation served as inspiration for the elaboration of a design specifically oriented to the digitization of film reels in a state of fragility.

NoGap 2D FilmScan, a new approach

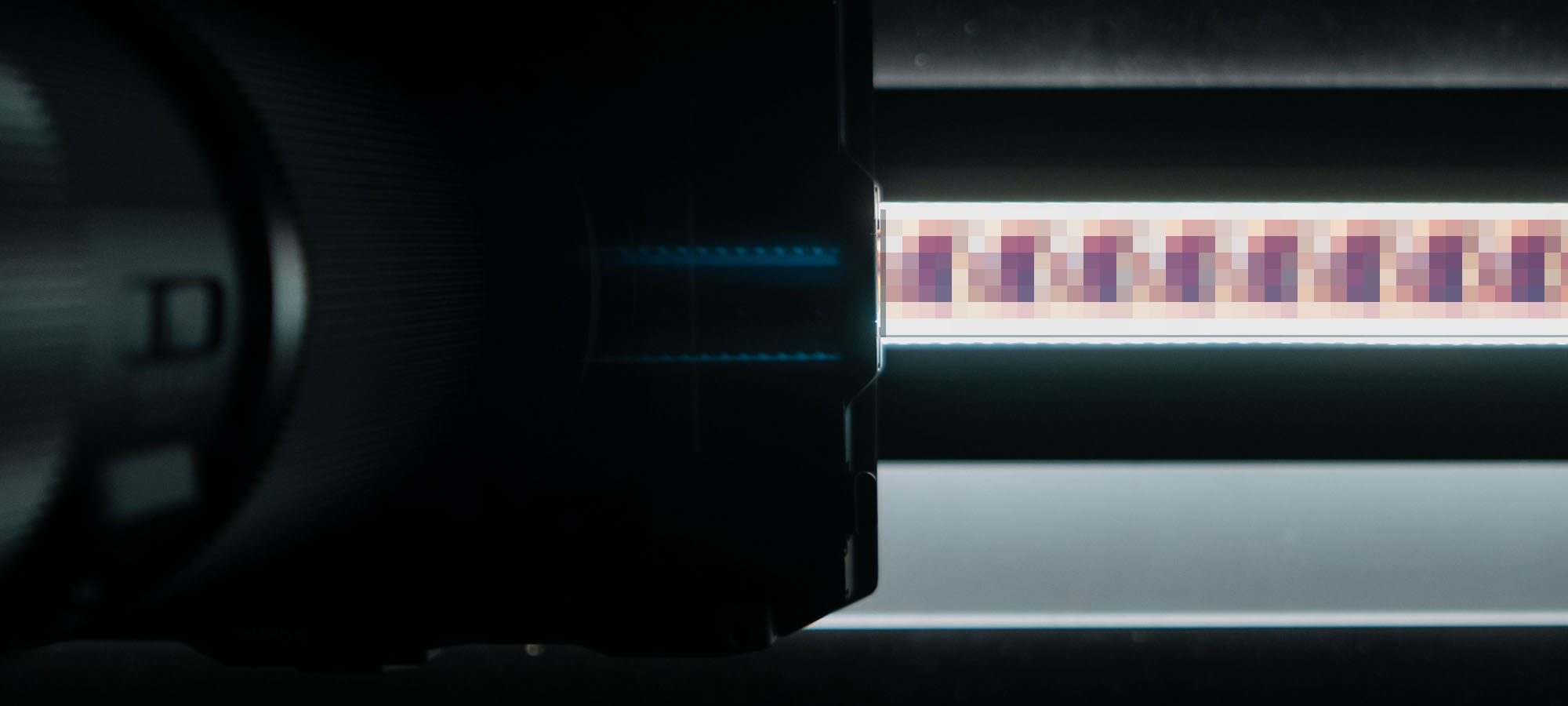

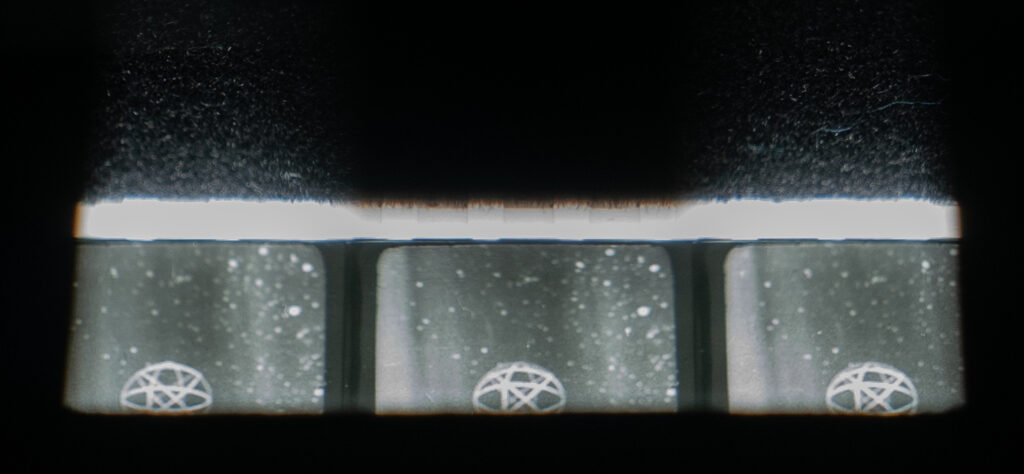

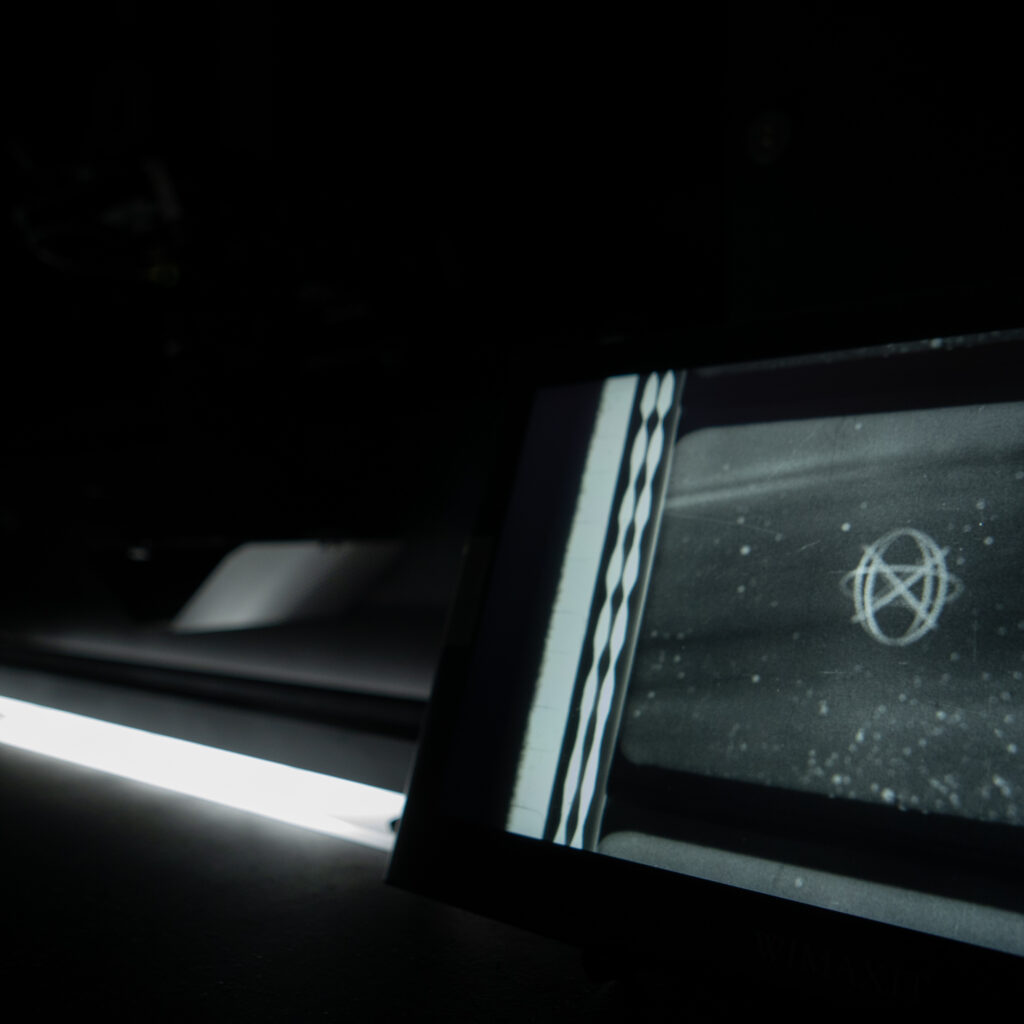

NoGap 2D FilmScan is the result of a development materialized in an 8K DCI scanning system in RAW format for 35mm film that eliminates tension forces or the use of mechanisms with sprocket rollers to transport the film.

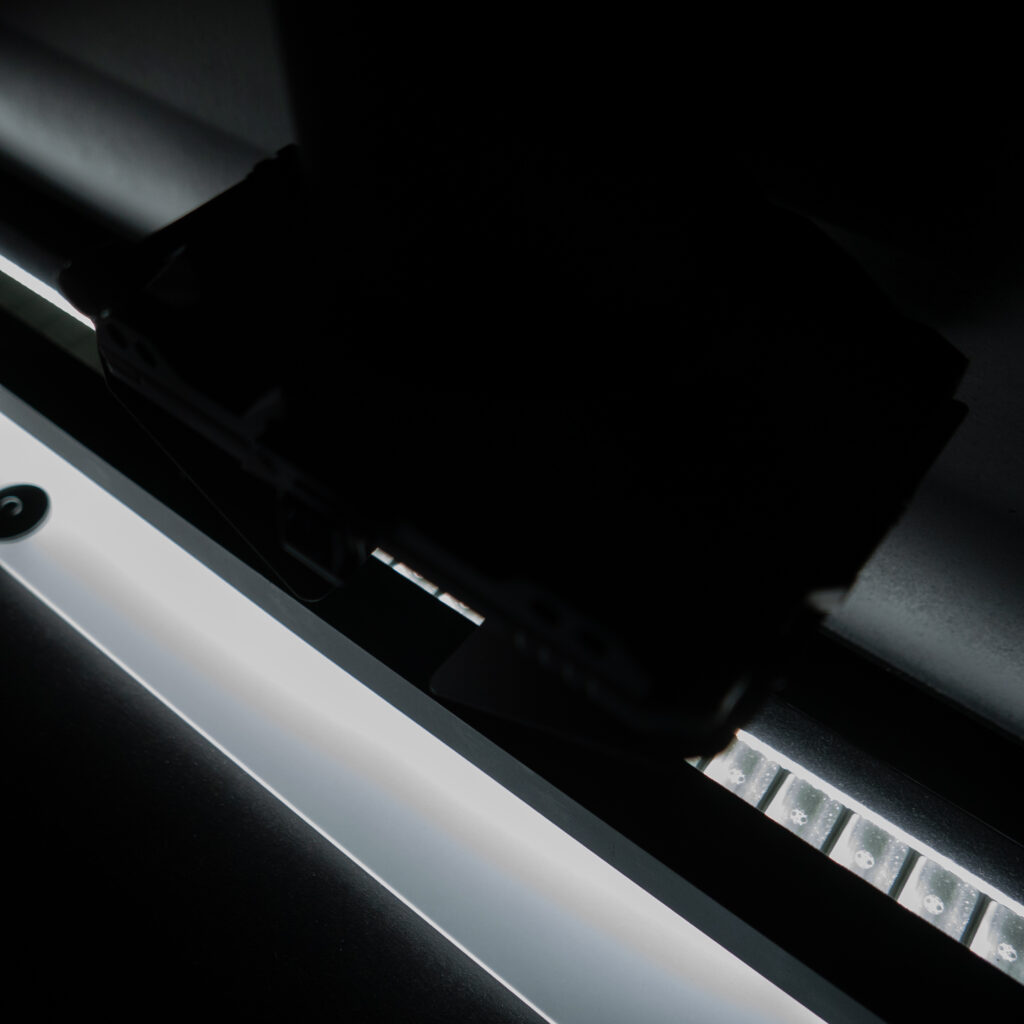

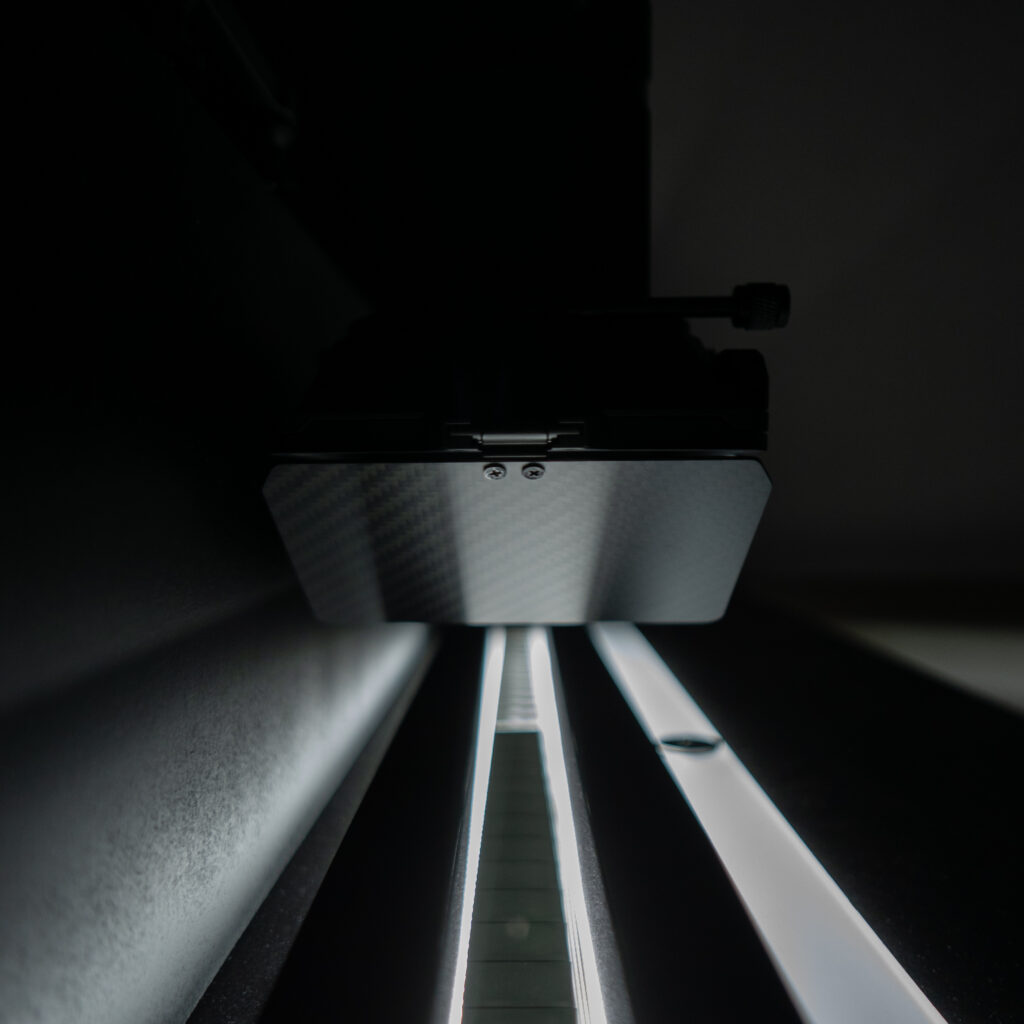

Unlike usual, and to minimize the stress suffered by the reel of the film support, in this design, it is the digital sensor that moves over the frames of film segments arranged by the technician on a backlit window.

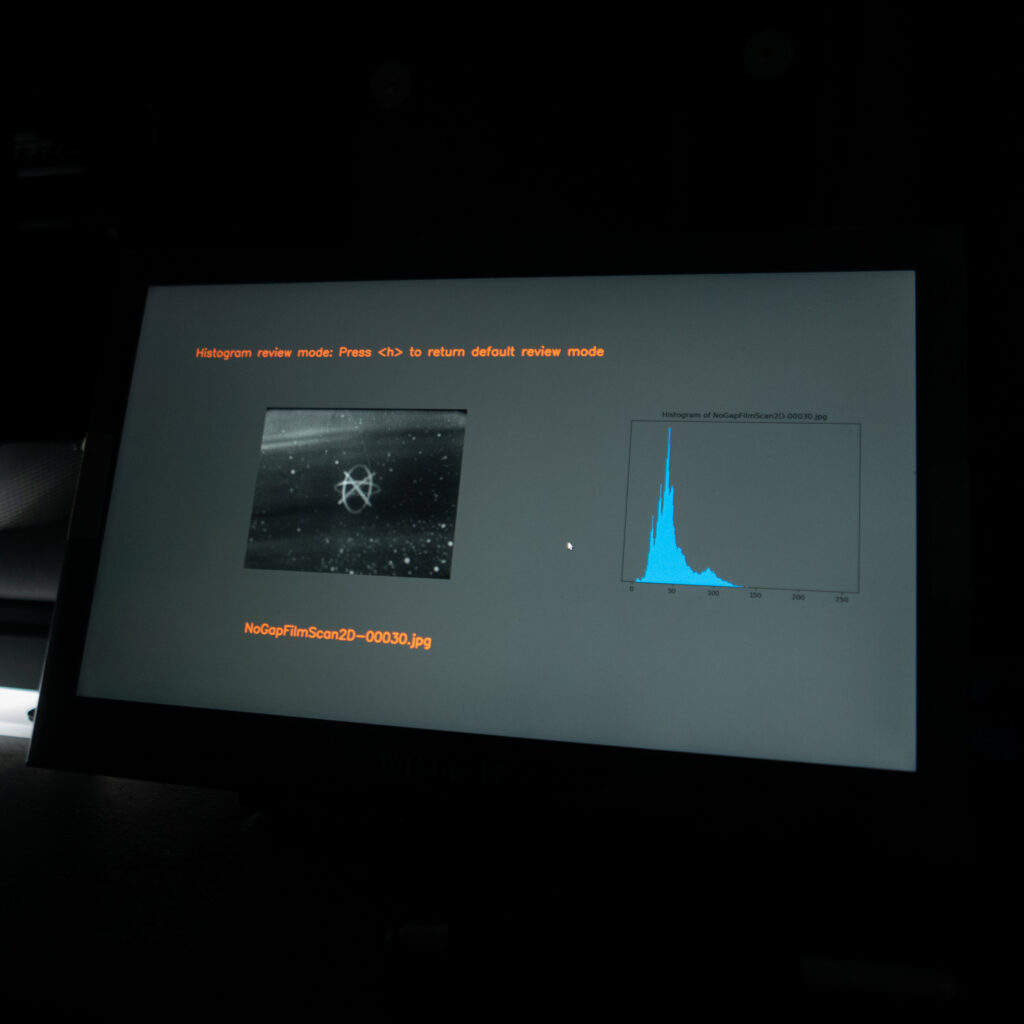

The system, based on Python on Linux, relies on Computer Vision technology to deliver an 8K DCI RAW image sequence with lossless 14-bit processing.

As a solution designed mainly to assist film libraries and film material preservation organizations, there are technical requirements that have always been present in its development. Consequently, NoGap 2D FilmScan integrates into the system an ultra-high-resolution camera that offers images with a wide dynamic range, high latitude, and rich color depth along with excellent optical quality.

In addition, to support the compatibility of scanned content, now and in the long-term future, the format of the files delivered by the system is RAW image data, in the standard digital negative format or DNG specification. Many professional archivists and preservationists in institutional settings* have adopted the DNG standard for archival purposes due to the great benefit of having the raw information from the scan in an open architecture format.

NoGap 2D FilmScan 8K digitization system delegates to the technician the final positioning of the segment to be digitized to guarantee transport of the film according to the needs imposed by its fragility, but autonomously assumes all those processes that allow it to be automated both in the supply of film and in digitization.

The treatment of the DNG image sequences, delivered by the NoGap 2D FilmScan 8K digitization system, within applications such as Davinci Resolve, Nuke, o DIAMANT-Film Restoration, allows to fully exploit the possibilities in digital image manipulation and restoration within a native RAW workflow with 32-bit floating point color processing precision.

Characteristics

- The NoGap 2D FilmScan 35mm film scanning system delivers a RAW image sequence that allows for a clean crop 8K DCI resolution, or a full frame overscan, with film perforations, at a higher resolution than 8K, thus allowing image stabilization workflows to be adopted without loss of resolution nor content information.

- Uniform illumination window based on white LED (CRI > 90).

- Working modes:

- Simplified project management

- Capture mode

- Capture monitoring modes:

- Review of the full frame (overscan)

- Histogram review of cropped image, without perforations, (clean crop)

- HDR mode. This working mode allows generating image sequence files that store the information of up to 5 different f-stops per frame to absorb the high dynamic range of some 35mm films.

- Motorized module with feed reel to automatically supply the segment of film to be digitized.

- Motorized module with takeup reel, activated at will by the technician, for the collection of the already digitized film segment.

- Python toolset to monitor capture integrity and automate image manipulation processes with the possibility of conversion to other formats such as 8, 10, 12, or 16-bit TIFF or DPX in ACES color space for more traditional workflows.

Want to know more? Don’t hesitate to get in touch at: nogap2Dfilmscan@lasala1.com